|

Deutscher Text >>>

Company profile

Promix Solutions AG, a “spin-off” of Sulzer, stands for mixing, foaming and cooling in plastics processing and polymer production. The company serves the industry with effective solutions for cost savings and quality improvements in extrusion and injection molding. A motivated team with long standing experience and extensive process and application know-how ensures excellent consultancy and service. The portfolio consists of mixing nozzles, melt blenders, foam extrusion systems, CO2/N2 Gas Dosing Stations, Key components for the production of low density foams and melt coolers.

â–ºWatch videos on Youtube

Mixing nozzles and static mixers for injection molding - Improve your process now!

You can solve many of your today problems in a fast and cost effective way without interrupting your production. Find the hidden potentials to further process optimizations. Save master batch costs of up to 30 % or reduce the cycle time.

For more information please click on the links below:

• No color streaks and flow lines

• Improved surface appearance

• Better incorporation of regrind material

• Better balancing of cavities in hot runner systems

• Better tolerances

• Increased tensile strength

• Close to maintenance-free processing of liquid silicone rubber

â–ºCase studies

â–ºMixing Nozzle Finderr

Promix mixing nozzle concept

The Static Mixer is installed directly in the nozzle of the injection molding machine. You can rely on an experienced partner replacing your existing nozzle with the suitable complete Mixing nozzle from our extensive mixing nozzle portfolio. Most of the mixing nozzles can be delivered within 1 to 2 weeks.

â–ºMixing nozzle inquiry form

Melt blenders for extrusion

Do you wish to optimize your extrusion process? Promix offers you effective static mixer and melt blender solutions including extrusion housings at low investment cost.

Promix melt blenders offer you

• Higher throughput

• Excellent distribution of all additives

• Consistent quality and optimal inflow of melt into the die

• Elimination of flow lines

• Homogenious temperature and velocity

Application examples:

For more information please click on the links below:

• Cable sheathing

• Compounding

• Extrusion blow molding

• Pipe extrusion

• Rigid PVC & rubber extrusion

• Sheet & profile extrusion

• Thin film & blown film extrusion

• XPS foam boards

Promix melt blenders for effective temperature homogenization

Thermoscan of PE coating film with and without Promix melt blender

What we offer

• Design, layout and manufacturing of melt blenders / static mixers

• Custom-made housings including heater bands and thermocouples

• Short delivery times

• High quality standard

â–ºMelt blender inquiry forms extrusion

Promix foam extrusion - Retrofit solution for physical foaming in extrusion

Promix foam extrusion is a unique, licence free technical concept for foam extrusion. Promix foam extrusion allows to cut production cost of semi-finished products due to reduced raw material consumption. It is also used to substitute chemical foaming additives with eco-friendly blowing agents as CO2 or Nitrogen.

What we offer

Promix foam extrusion is a comprehensive solution including all required equipment and services to achieve your microcellular foam product:

• Thorough analysis of your current extrusion process and your targeted foam application

• Foaming systems for precise injection and effective solving of supercritical blowing agents including melt

cooling

• Reliable and very accurate gas dosing stations

• Foam dies and die modifications, annular dies for light foam applications

• Melt coolers for optimized foaming results

• Pilot testing and sample production on site or in our test facilities

Microcellular foams with Promix foam extrusion system

Examples of use

Promix foam extrusion systems are in industrial use for many different applications and products. Mono- and multilayer foam lines are in operation with capacities of 5 kg/h up to 2000 kg/h producing superior foam products including microcellular foams. Here below are a few examples.

Your benefits

• Significant cost savings due to density reductions by 10 - 70 %

• Lower running costs and further reduced foam densities compared to chemical foaming

• Eco-friendly light weight products, use of natural blowing agents such as CO2 or N2

• Superior foam properties and process consistency

• Easy switch from foamed to non-foamed products

• Fast and easy installation, quick start up

• No licence fees, no running royalties

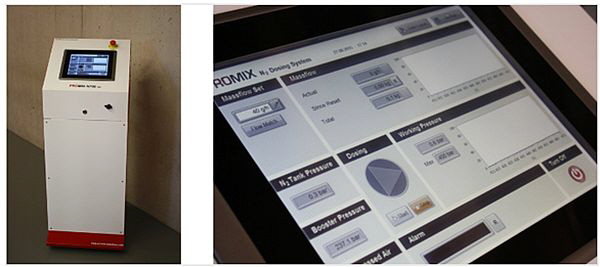

CO2 and N2 Gas dosing stations for physical foaming

Promix Gas Dosing Stations for physical foaming have been developed to suit the specific needs of foam extrusion applications. Extremly high dosing accuracy, reliability and easy operation are the key features of Promix gas dosing systems. No matter if process monitoring with trend charts and user settable alarms, data acquisition, flow match with extruder output and many more, Promix gas dosing units provide all the required features for state of the art foam production. Furthermore, implementation in extruder control via fieldbus system is also possible.

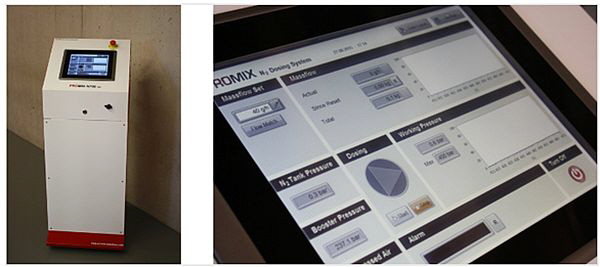

Promix gas dosing system for physical foaming

Main characteristics Promix gas dosing stations

• Massflow from 1 g/h up to 3000 g/h

• Delivery pressure up to 700 bar

• Convenient operation via 12,1” Touch Screen

• User settable limits for full process control

• Trend charts for pressure and flow over time

• “Flow match” function to synchronize mass flow with extruder output

• Implementation in extruder control via fieldbus system possible

• Data acquisition via USB port

• Remote maintenance capability

Melt Coolers and Heat Exchangers

Do you wish to cool down your polymer melt? Promix offers you very efficient melt coolers and heat exchangers for viscous and high viscous fluids and melts.

Promix Melt Coolers improve your process

- Very high cooling efficiency and accurate outlet melt temperature control

- No fouling or blocking problems due to a well-mixed single flow

- Narrow residence time distribution

- Short installation length

- Low pressure drop

Melt Cooler for highest efficiency

Melt Cooler concept

In cooling processes viscous fluids tend to deposit at the cooling wall sections (fouling) leading to reduced cooling efficiency. In the Promix Melt Cooler (PMC) the melt flows in a single stream through the cooler. The cooling media flows in special pipe bundles arranged similar to those of the Promix mixing elements. The intense mixing together with the very high heat exchange surface area leads to effective cooling with very limited risk of fouling. Due to a void volume of about 75 % the resulting pressure drop in a PMC is rather low. The PMC can as well be used for gentle heating with only small temperature difference between heating media and fluid.

Fill in the PMC inquiry in order to get an offer or contact our experts for further questions.

Promix Melt Cooler in operation

Key components for the production of XPS, XPE, XPP, XPET low density foams

Promix offers relevant key components to optimize production of low density foams as for example fabrication of XPS insulation boards, XPE foam film or XPP, EPE thermoforming sheet. Implementing Promix key equipment generally results in lower foam densities, improved cell structure and an increased line output, leading altogether to significantly lower production cost. Whether it is a tandem or long single screw line, thermal insulation boards, packaging film or insulation for tubes or pipes: we will analyse your current line concept and are going to propose a solution to increase your profitability.

Benefits of Promix key components for low density foams

XPS Insulating board

• Uniform cell size and more consistent foam structure • Uniform cell size and more consistent foam structure

• Increased throughput, especially for thick boards

• Lower foam density

• Faster start-up time

• Savings of blowing agent

XPE foam film and profile

• Lower foam density • Lower foam density

• Uniform cell structure

• More narrow thickness tolerances

PS foam for food packaging (XPE)

• Lower foam density • Lower foam density

• Increased stiffness/rigidity

• Improved thermoformability

• More narrow thickness tolerances

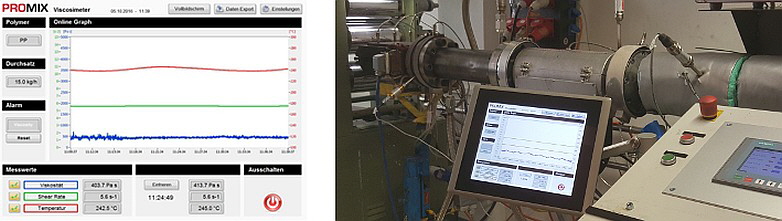

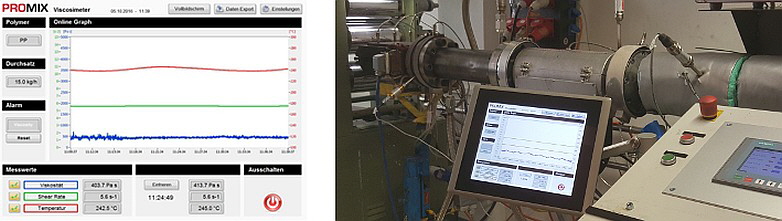

Viscosity measurement, accurate and inline - true real time quality control

Control the production quality of your extrusion line with Promix Visco-P continuously and in real time. Avoid poor production quality issues and scrap. Visco-P is a true inline viscometer which measures viscosity directly in the melt stream and requires no bypass. The Visco-P continuously monitors raw material quality and process conditions. Convince yourself. Ask us for a test unit.

Your benefits

• Continuous real time control of raw material quality and process conditions

• Very accurate inline viscosity measurement without bypass

• Suitable for all viscous fluids

• MFI / IV-calculation mode

• Will be used in combination with Promix static mixers leading to additional value by improved melt and

temperature homogeneity

How it works

A special Promix static mixer module, installed in the extrusion line, is the physical point for measuring process variables. The calculated results are displayed continuously and in real time on an industrial PC with touch screen. In addition to measuring the melt viscosity, the Visco-P will also calculate the MFI or IV value of the real melt.

The Promix static mixer module creates excellent blending of the polymer melt which improves thermal homogeneity and surface quality, reduces thickness tolerance variations of the extrudates, and often leads to an increased output rate. Visco-P is in operation in many applications such as PET and PE extrusion and for the processing of polymer melts containing blowing fluids.

Promix® Visco-P for accurate inline viscosity measurement in extrusion

Visit us at the Fakuma. We would be pleased to meet you on our booth:

Hall A2 / Booth 2105

|

• Uniform cell size and more consistent foam structure

• Uniform cell size and more consistent foam structure • Lower foam density

• Lower foam density • Lower foam density

• Lower foam density

Promix Solutions AG

Promix Solutions AG