|

Deutscher Text >>>

The initial aims of the company were to carry out development, research and updating of products for the cleaning of injection presses, extruders, blowing machines and film blowing plants: in fact the presence and the use of plastic materials with new chemical formula on one side, and the requirement of industries for new specific products on the other side, need a continuous research and development.

Today Ultra Plast is a well known brand worldwide and Ultra System as a producer of only purging compound is considered a reliable supplier for the solution of any purging/cleaning issue in material processing; we can offer specific products de- pending on the industrial sector, at packaging industry, medical/pharmaceutical and cosmetics, automotive, electrical and household appliance industries.

AN EFFICIENT PURGING COMPOUND CONTRIBUTES TO ENERGY AND MATERIAL SAVING

We support our customers in improving the production by reducing waste production, machine downtime and costs.

â–şMore information can be found here.

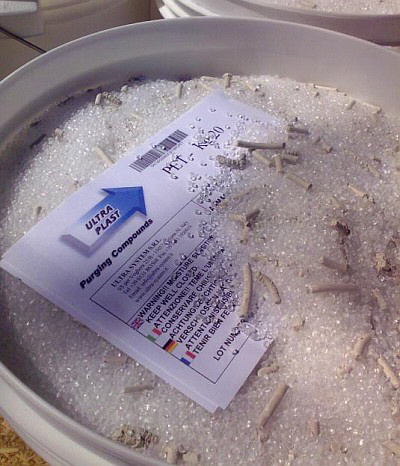

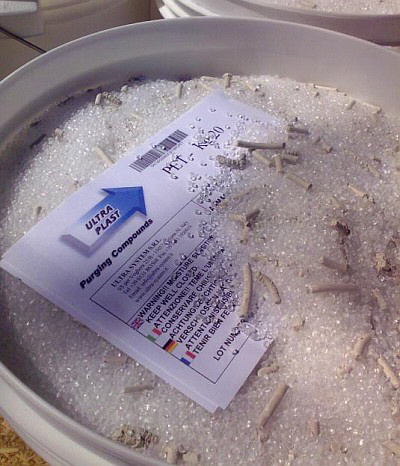

ULTRA PLAST - a brand new cleaning product in chips,

ULTRA PLAST, a brand new cleaning product in chips, eliminates all your problems when changing color and/or material. After severe tests and experiments, carried out by our technicians and our analytical laboratory instruments, this compound has being constantly improved.

How does it work?

It is not abrasive and functions with a chemical reaction. Thanks to its particular composition, colour, incrustations, black spots, rust and any impurities will be softened, removed and ejected from the machinery.

In this new formula an expanding and foaming agent makes it still more efficient, specially for the most difficult situations: the machines with degassing and the plasticizing accumulators.

Ultra Plast cleans at the temperature of the previously worked material and does not need any waiting time during cleaning cycle.

Advantages:

• Non toxic

• No waiting time during cleaning operation

• Safe and easy handling. Excellent efficiency

• Saves time for the cleaning operation. No raw material waste

• No smell: no unhealthy gas production

• No damage for your machines: no solvent or abrasive material content

• If used frequently, it protects steel from oxidation making cleaning operations easier and faster

• All components of Ultra Plast compound are safe according FDA

• Certification according to CE 2002/72 and 10/2011 for the contact with food or drinks

Products - Info >>>

HIGH grades: Purging for PC, PC/ABS, SAN, ASA

ULTRA PLAST HIGH-C FOR SCREW AND HOT RUNNER

Color or material change for injection, extrusion, hot runners, blowing with and without plasticizing accumulator.

This brand-new compound is particularly efficient in purging highly transparent materials such as PC, PS and PMMA, removing also the "milky shadow", a big issue in high-quality pieces.

ULTRA PLAST HIGH

Color or material change for injection, extrusion, hot runners, blowing with and without plasticizing accumulator.

ULTRA PLAST HIGH-HS (SPECIFIC FOR HOT RUNNER)

Color or material change for injection machines, with or without hot runners. This compound can be molded.

PO grades: the best purging for polyolefines

THE NEW ULTRA PLAST PO-C: ONLY ONE PRODUCT FOR SCREW AND HOT RUNNER

ULTRA PLAST P-O

Color or material change for injection, extrusion, hot runners, blowing machines with and without plasticizing accumulator. This compound is made to be particularly efficient on polyolephines.

ULTRA PLAST PO-HS (SPECIFIC FOR HOT RUNNER)

Color or material change for injection machines, with or without hot runners. This compound is made to be particularly efficient on polyolephines and can be molded

ULTRA PLAST PO-C (FOR SCREW AND HOT RUNNER)

Color or material change for injection machines, with or without hot runners. This compound is very efficient on screw and hot runner, so you need only one product for both.

ULTRA PLAST ECO-PO,

Specific for poliolephines, is at 70% biodegradabile and can be regranulated and reprocessed with waste production (sprues and trimmings) or be processed with other virgin poliolephines.

Thanks to this purging compound time and costs during colour change operations as well as environmental impact is sensibly reduced.

ULTRA PLAST PO-E

Color or material change for injection, extrusion, blowing machines with and without plasticizing accumulator. A special version of PO grade : for extremely difficult cases of color change or black specks

Low impact purging solutionn

ULTRA PLAST CE-E

A special concentrate grade to be mixed at 5/10% with the production material ,

particularly suitable to clean film blowing plants and blow molding machines.

The new formula of CE-E can be used on film blowing plants without breaking the bubble.

Ultra Plast HT: the solution for special polymers

Color and material change for high temperature polymers injection and extrusion. Often used for the intermediate processing between high and medium temperatures. Particularly indicated for materials with flame-retardant.

PET grades: Easier preform production

ULTRA PLAST PET-C

Color or material change for injection, extrusion, hot runners, blowing with and without plasticizing accumulator. Particularly suitable for the production of preforms and containers for food, pharmaceutical and cosmetic industries. This new-brand material can be used on screw and hot runner, with excellent cleaning effect.

ULTRA PLAST PET

Color or material change for injection, extrusion, hot runners, blowing with and without plasticizing accumulator. Specially for the production of preforms and containers for food, pharmaceutical and cosmetic industries..

ULTRA PLAST PET-HS (SPECIFIC FOR HOT RUNNER)

This grade, specific for PET processings (including preforms) can be injected directly into the mold and be processed like normal PET production. Dead times such as screw shifting , mold changes and purge during the cleaning process are eliminated, cleaning becomes faster and production costs are reduced.

UltraGREEN - Info >>>

We are committed to economical and environmental sustainability.

We believe that our balanced approach to these two interdependent elements play a key role in our ongoing success.

To this purpose we developed two new grades of purging compound, Ultra Plast BIO PET, with a new completely biodegradable formulation suitable on PLA preform production, and Ultra plast ECO PO, 70% biodegradable and 100% recyclable.

For all bio-materials processors, a brand-new product

ULTRA PLAST BIO-PET

Specific for the perform moulding with PLA material, this purging compound can be used for the cleaning of screws, barrels and accumulators of injection machines.

As it is 100% biodegradable it guarantees a low environmental impact also during cleaning operations on those machines where bio-materials are processed.

ULTRA PLAST ECO-PO

Specific for poliolephines, is at 70% biodegradabile and can be regranulated and reprocessed with waste production (sprues and trimmings) or be processed with other virgin poliolephines.

Thanks to this purging compound time and costs during colour change operations as well as environmental impact is sensibly reduced.

Companyvideo

Visit us at the K show 2016. We are looking forward to welcoming you on our stand (hall 13, stand D89 / hall 12, stand A51-12). |

Ultra System S.A.

Ultra System S.A.